Drive less, do more with m.Inject™. It installs in minutes, work with nearly every pump, and allows you to remotely monitor and manage all your injection operations from your desk or vehicle.

m.Inject™ is designed for effortless installation and intuitive operation, ensuring it's not only simple to install, but easy to use. With m.Inject™ your team can monitor and manage injection operations from their desk, enhancing efficiency, improving injection accuracy, minimizing losses from undetected problems such as leaks, low battery voltage, damaged components, etc.

Features and Benefits:

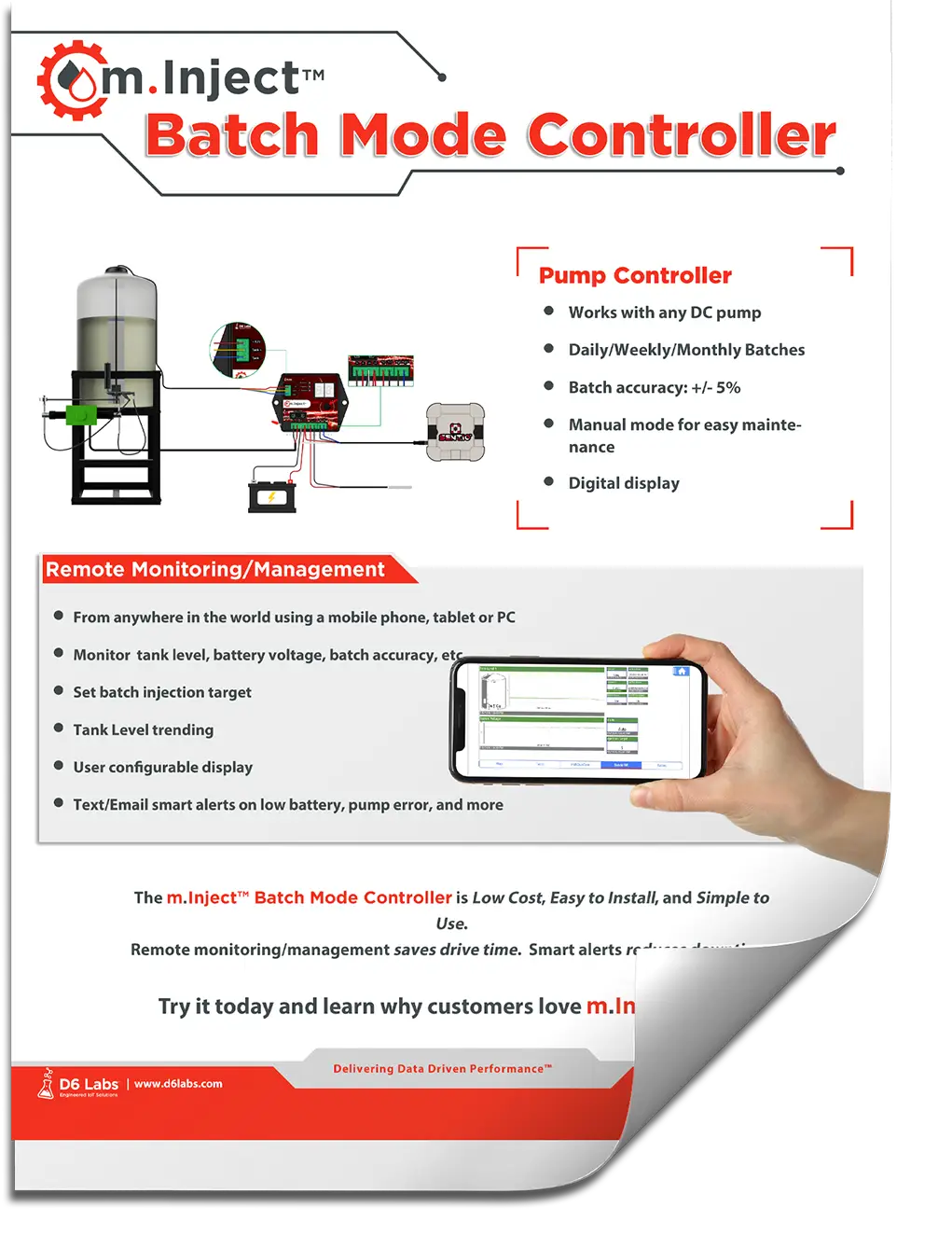

The m.Inject™ pump controller is low cost, easy to use, and extremely flexible. It works with any brushed DC or pneumatic pump* and provides accurate control over injection rates.

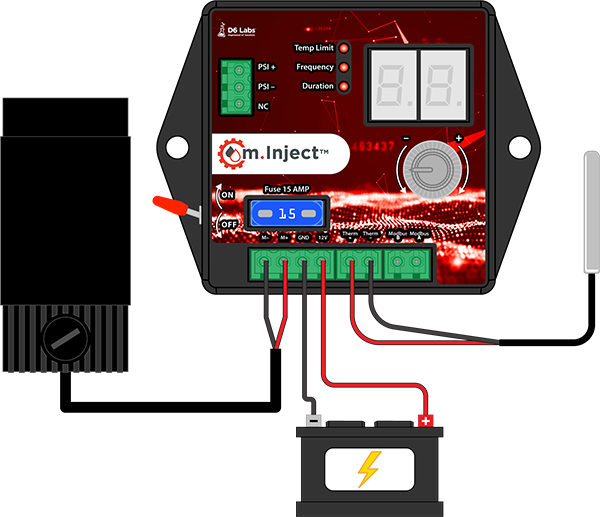

The on-board digital display shows current settings, battery voltage, temperature, and tank level (optional).

The on-board Modbus RTU port can be used for local or remote SCADA. All settings and monitored parameters are mapped to holding registers for easy access by a PLC or HMI.

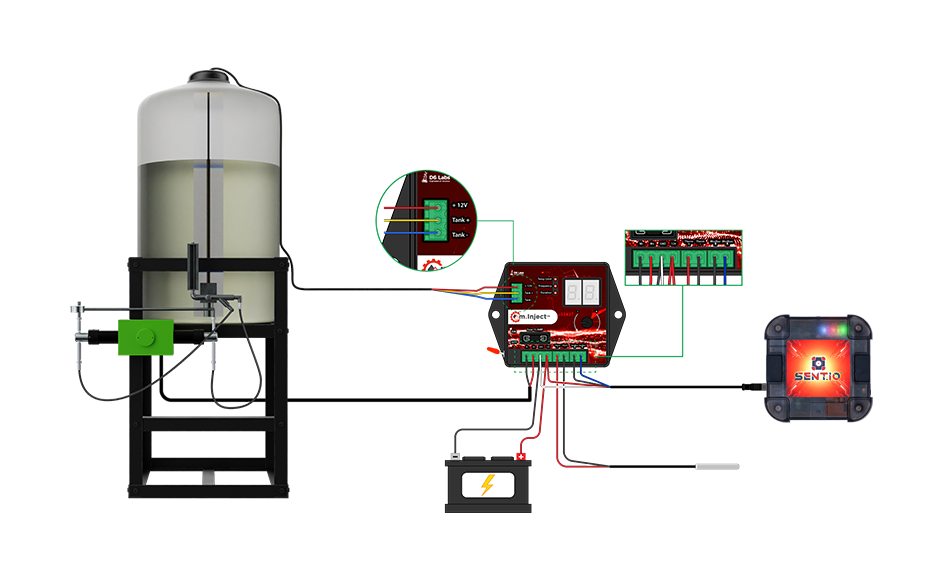

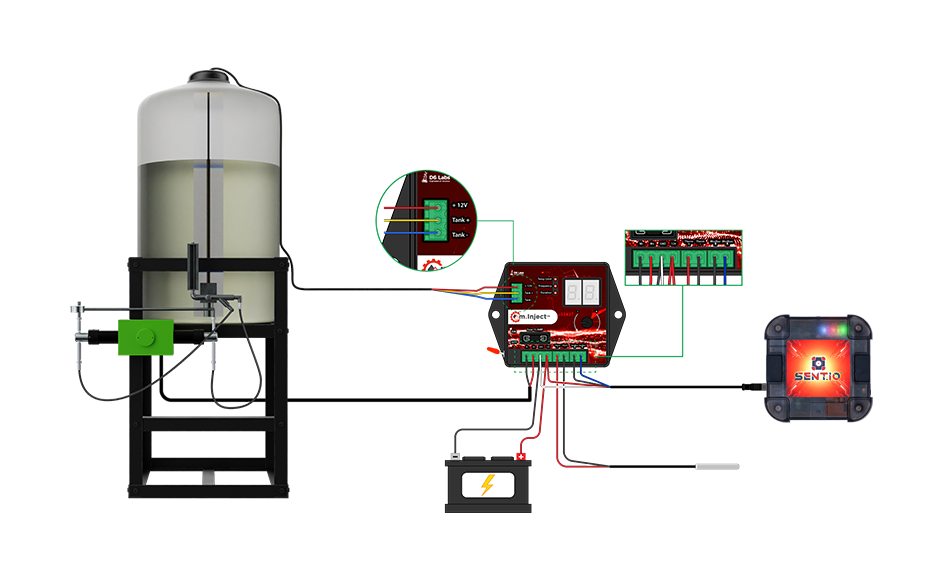

When connected to a Sent.io™, the controller can be monitored and managed remotely via our cloud platform and it can be expanded with additional I/O for custom applications.

* - pneumatic pumps require an external bistatic 12V DC valve.

m.Inject™ can be quickly be installed in new and retrofit applications. Wiring is as simple as providing power and connecting the motor.

Once the controller is installed and power is applied, the LED display will default to displaying battery voltage. Press the knob to cycle the LED display through the settings and set Frequency, Duration, and the temperature threshold according to your application requirements. Finally, flip the switch on the side of the controller to the on position to start operation.

When pump maintenance is required, flip the switch to the off position. If you need to move the pump to get it in the right position to adjust packing, set the Frequency to 10 and the Duration to 6, then quickly flip the switch on and off until the pump is positioned properly.

The Sent.io™ Direct2Cloud IoT gateway is a low cost add-on for the m.Inject™ injection pump controller that provides immediate and profound benefits including:

Sent.io™ can be added to any m.Inject pump controller in a matter of minutes. It really is as easy as 1..2..3..

That is all there is to it. With those 3 simple steps complete, you can now remotely monitor and manage your injection system from anywhere in the world using a PC, tablet, or mobile phone.

In CI (Continuous Injection) mode, you set a target injection rate in gallons per day (GPS) and m.Inject™, working in conjuction with our cloud platform, will continuously adjust the Frequency and Duration settings to control the injection rate within +/- 10% of the target you set. Unlike other systems that use expensive automated sight glass tests, our solution monitors tank level in real-time to determine instantaneous injection rate and then uses that data to adjust pump settings.

m.Inject™ is the most cost effective automation package for chemical injection and our accuracy rivals best in class. Fewer moving parts means less failures and less maintenance. And because its a D6 Labs solution, its also the easiest to install and use.

Other than a Sent.io™ to connect m.Inject™ to the cloud, no extra hardware is required and there are no additional fees for using CI mode with m.Inject.

In batch mode, you provide a schedule for when you want a batch to run and the size of the batch and m.Inject™, working our cloud platform, will automaticaly start the pump at the scheduled time and run until the batch is complete with an accuracy of +/-5% of target.

The schedule is calendar based and is extremely flexible, allowing you to setup batches to run daily, certain days of the week, and certain days of the month. You can change the schedule at any time and the controller will automatically adjust. There is no need to manually start the controller to establish the start time of the first batch - the calendar based operations ensure that setup is quick and simple.

Other than a Sent.io™ to connect m.Inject™ to the cloud, no extra hardware is required and there are no additional fees for using CI mode with m.Inject.

When connected to our cloud platform via Sent.io™, m.Inject collects and reports tank level readings every 5 minutes. This data is stored in our platform and is available for analytics and reporting, providing your company with important tools to improve efficiency through data driven process and decision making. Using this data, our platform calculates daily injection rate,

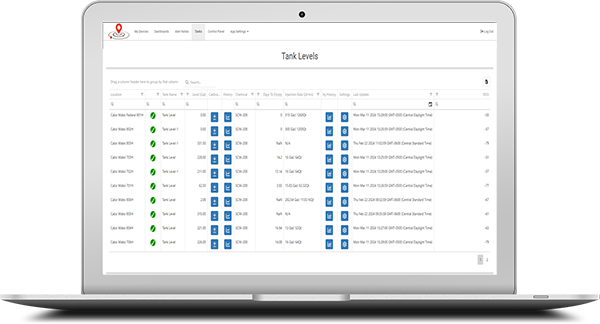

Our tank inventory tool provides powerful analytics capabilities including the ability to monitor tank level history, injection history including deviance from target, days to empty for all tanks, and current injection rate and tank level. Group the tanks by chemical and sort by days to empty to quickly find the tanks that are closest to empty for each chemical type. Or, group the tanks by location to view tank data by location; then you can sort by days to empty to quickly find the tanks that are closest to empty for each location. Export the data to an excel spread sheet for off-line analysis and data manipulation.

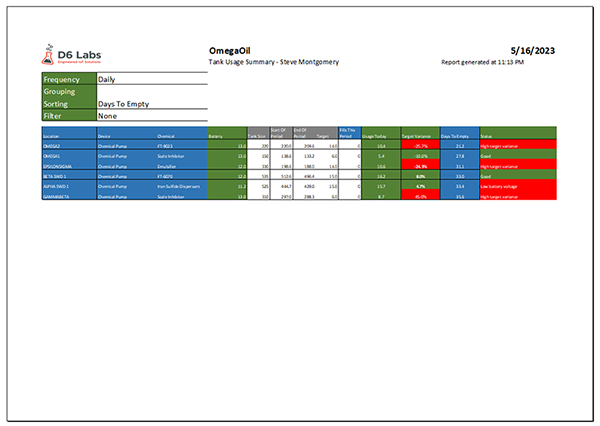

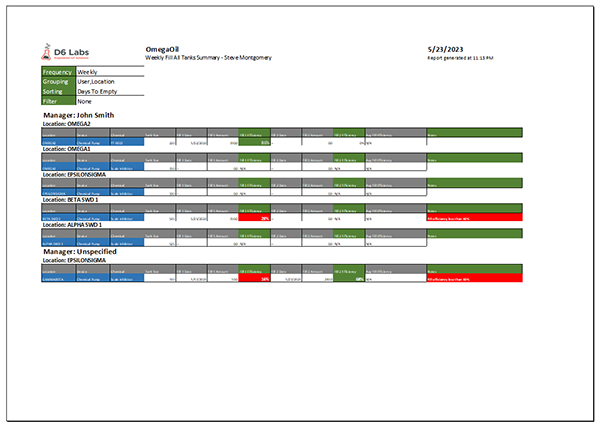

Tank related reports can be configured for automatic delivery to your email every day, week or month. The Tank Usage report shows the current tank level, injection rate target, current injection rate for the period, and deviation the target and the actual injection rate. This report allows you to quickly identify which locations are performing well and which locations are having problems, allowing you to focus your time in only those places where it is needed. The Tank Fill report is useful for improving your fill route efficiencies. Using tank level data, the report detects up to 3 fill events in the report period and reports the tank level at the start of period, the tank level at the end of period, the size of each fill, and most importantly, the fill efficiency score for each tank.

The Sent.io™ Direct2Cloud IoT Gateway, Whisker.Block®, Smart.Hub™, and Whisker.io® cloud app are designed & built by our team of engineers and technicians in the heartland of the USA. We do not outsource any aspect of our technology platform and when you need support, you can talk directly to our engineering team for help. If you have an idea that could improve our products or application, let us know - most of the great features we have today started as suggestions brough to us by customers.